Showroom

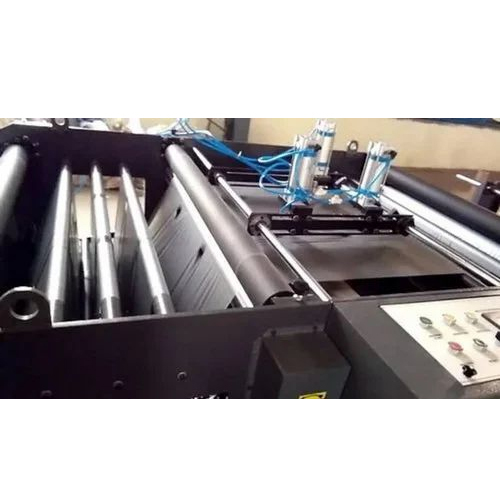

Our Agricultural Mulch Film Punching Machine is a high-performance solution for enhancing efficiency in farming operations. Designed for precision and reliability, it efficiently punches holes in mulch films, facilitating better soil aeration and moisture retention. With its user-friendly design and durable construction, it streamlines agricultural processes for optimal crop growth and yield.

Explore our Mulch Film Punching Machines, crafted to boost agricultural productivity. Adjustable for different film types and thicknesses, they optimize crop yield and quality. Trust our durable, user-friendly equipment to streamline your farming processes effectively.

Mulch Film Hole Punching Machines are used to make several types of pouches and have many adjustable features. They are suited for making Bottom sealed Shopping bags, Bread bags, Diaper Bags and other hygiene products.